-

Gunning

Gunning

-

Specialised link

Specialised link

-

Sea Launch

Sea Launch

-

Endergonic

Endergonic

-

Greenstick fracture

Greenstick fracture

-

Ischaemic

Ischaemic

-

Glaciation

Glaciation

-

Polysynthetic

Polysynthetic

-

Active fault

Active fault

-

Cryptanalysis

Cryptanalysis

-

Geomorphosis

Geomorphosis

-

Colposcopy

Colposcopy

-

Tumour antigen

Tumour antigen

-

Biot's law

Biot's law

-

Altruism

Altruism

-

H2 histamine antagonist

H2 histamine antagonist

-

Clinical trial

Clinical trial

-

Group of galaxies

Group of galaxies

-

Genetic fingerprinting

Genetic fingerprinting

-

Hypha

Hypha

-

True anomaly

True anomaly

-

Melliferous

Melliferous

-

Aspirin

Aspirin

-

Fluid inclusion

Fluid inclusion

-

Convulsion

Convulsion

-

Aldebaran

Aldebaran

-

Down quark

Down quark

-

H.323

H.323

-

Autoclaved aerated concrete

Autoclaved aerated concrete

-

ATV

ATV

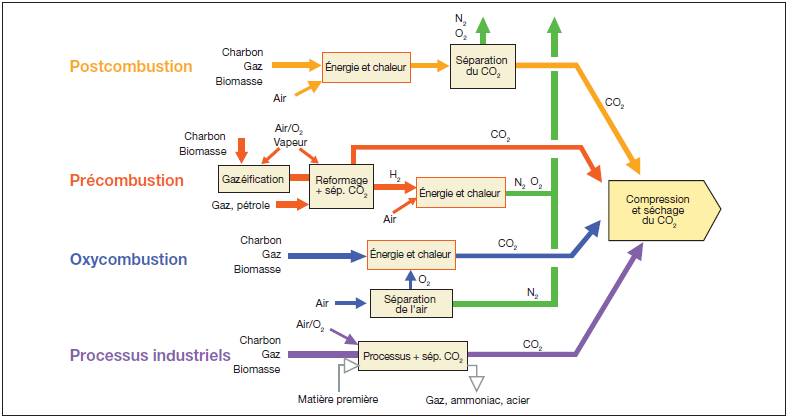

Pre-combustion separation of CO2

The pre-combustion separation of CO2 is one of the techniques used for capturing and sequestering CO2. This process consists in treating fuels (oil, coal...) upstream of their combustion.

Principle of pre-combustion separation of CO2

These fuels are first gasified in a reactor exposed to air, water vapour or pure oxygen, in order to produce a syngas composed of carbon monoxide (CO) and dihydrogen (H2).

This syngas then passes through a conversion reactor where it is exposed to water vapour. The carbon monoxide reacts with the water (H2O) and produces carbon dioxide (CO2) and more hydrogen (H2).

The pressure and concentration of the carbon dioxide (from 15 % to 60 % dry volume) then facilitates the separation of CO2 and hydrogen. The concentrated CO2 can then be sequestered.

Advantages and disadvantages ofpre-combustion separation

This process is more complex and more expensive than post-combustion separation, but it produces a more concentrated gas under high pressure, which makes separation easier. It is generally applied in cycle power stations combined with incorporated gasification.

A diagram showing different processes for the industrial capture of CO2, including pre-combustion separation (in red). © Giec 2005

A diagram showing different processes for the industrial capture of CO2, including pre-combustion separation (in red). © Giec 2005

Latest

Fill out my online form.